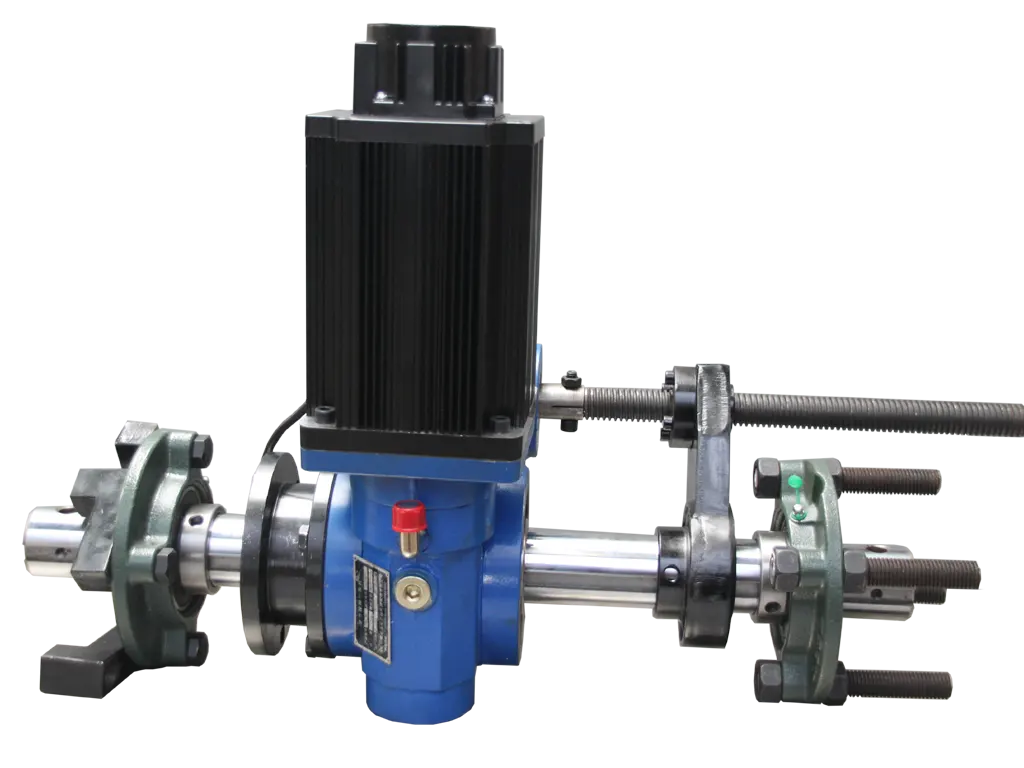

Portable Line Boring Machine SLB50

Key Features:

- High-Power Servomotor: Robust motor for precise control and high torque.

- Multifunctionality: Capable of line boring, inner bore welding, and slotting.

- Stability and Precision: Engineered for accurate performance.

- 30mm Boring Bar: Includes a sturdy bar for various bore sizes.

- Facing tool: Includes a facing tool for 50mm boring bar.

- Portability: Designed for easy setup and use on-site.

- Durability: Built to withstand industrial conditions.

| Weight | 168 kg |

|---|---|

| Dimensions | 75 × 49 × 50 cm |

Original price was: $4,200.$3,600Current price is: $3,600.

99 in stock

Datasheet Download

The SLB50 portable line boring welding machine is a versatile tool designed for on-site machining and welding tasks in various industrial applications. Here’s an overview of its features and capabilities:

- Portability: It is compact and designed for easy transportation to job sites, allowing for on-site repairs and machining without the need to transport large and heavy machinery.

- Line Boring: The machine is primarily used for line boring operations, which involve enlarging or repairing holes that have already been drilled or cast. This is crucial in industries where precise alignment and sizing of bores are essential.

- Welding Capability: In addition to line boring, the SLB50 model integrates welding capabilities. This allows operators to not only machine but also repair worn-out bores and surfaces by welding and then machining them back to specification.

- Precision Machining: It offers high precision machining to ensure accurate results, crucial for industries such as mining, construction, shipbuilding, and oil and gas.

- Versatility: The machine is versatile enough to handle various materials and bore sizes, making it suitable for a wide range of applications where on-site repairs or modifications are needed.

- Ease of Use: Designed with user-friendliness in mind, the SLB50 typically features intuitive controls and setup procedures, allowing operators to quickly set up and start machining operations.

- Applications: Common applications include repairing equipment like engine blocks, gearboxes, and hydraulic cylinders, where precise boring and welding are required to restore functionality.

- Durability and Reliability: Built to withstand demanding environments, the SLB50 is engineered for durability and long-term reliability, ensuring consistent performance even in challenging conditions.

Overall, the SLB50 portable line boring welding machine combines the capabilities of line boring and welding in a portable package, offering flexibility, precision, and efficiency for on-site machining and repair tasks across various industrial sectors.

SLB50 Portable Line Boring Welding Machine

| SPECIFICATIONS | INCH | METRIC |

| Bar Diameter | 1.97 in. or optional 1.18 in. | 50 mm or optional 30 mm |

| Boring Diameter | 1.38 – 9.84 in. | 35 – 250 mm |

| Inner Bore Welding Range | 2.36 – 9 in. | 60-230 mm |

| Max. Stroke | 9.84 in. | 250 mm (customizable) |

| Power Option | Electric | Electric |

Customer Reviews

Only logged in customers who have purchased this product may leave a review.

Frequently Asked Questions

What is a Portable Line Boring Machine?

A portable line boring machine is designed to bring precision boring capabilities directly to the work site rather than requiring the workpiece to be transported to a workshop. It typically consists of a boring bar, which houses the cutting tool, and a mounting system that allows it to be set up and operated on-site. This mobility makes it ideal for applications where disassembling large components for repair or modification is impractical or costly.

When is Line Boring Needed?

Line boring is necessary when cylindrical holes in equipment become worn, misaligned, or need to be resized. Common scenarios include:

-

Worn Bushings or Bearings: When the original bushings or bearings wear out, causing the hole diameter to increase.

-

Misalignment: Due to manufacturing defects or wear over time, holes may no longer be concentric or properly aligned with mating parts.

-

Size Modification: Sometimes, equipment needs to accommodate larger components, requiring existing holes to be enlarged.

-

How to Choose a Line Boring Machine?

When selecting a line boring machine, consider the following factors:

-

Size and Capacity: Ensure the machine can handle the diameter and length of the holes you typically work with. Machines come in various sizes to accommodate different workpiece dimensions.

-

Accuracy and Precision: Look for a machine that offers high precision, as this is crucial for achieving proper alignment and fit.

-

Portability and Setup: Evaluate how easily the machine can be transported to the job site and set up. Portable machines should be relatively lightweight and come with a straightforward mounting system.

-

Power and Speed: Consider the power source (electric, hydraulic, pneumatic) and the speed control options available. Higher power and adjustable speed settings provide versatility for different materials and hole sizes.

-

Tooling and Accessories: Check the availability and cost of tooling (cutting tools, boring bars) and any additional accessories needed for specific applications.

-

User-Friendliness: A user-friendly interface and intuitive controls can reduce setup time and operator training requirements.

-

Durability and Maintenance: Choose a machine built from robust materials that can withstand the rigors of industrial use. Easy access for maintenance and serviceability is also beneficial.

-

Additional Information Needed:

For a more specific recommendation, additional details about your typical applications, budget constraints, and any unique requirements (such as working in confined spaces or with non-standard materials) would be helpful. This information would allow for a more tailored selection of the right portable line boring machine for your needs.

Installation of Portable Line Boring Machine:

-

Prepare the Work Area:

- Ensure the work area is clean, stable, and large enough to accommodate both the machine and the workpiece.

- Clear any obstructions and ensure adequate lighting for visibility.

-

Setup the Machine:

- Position the portable line boring machine near the bore area, ensuring it is on a stable surface.

- If using a magnetic base machine, clean the surface where the magnets will attach to ensure a strong grip.

-

Mounting:

- Securely attach the machine to the workpiece using the mounting system provided (magnetic base, bolt-down clamps, etc.).

- Ensure the machine is aligned correctly with the bore axis of the workpiece to prevent inaccuracies during the boring process.

-

Check Alignment:

- Use precision measuring tools (like dial indicators) to verify the alignment of the machine with respect to the bore axis. Adjust as necessary to achieve precise alignment.

-

Secure the Workpiece:

- Depending on the size and configuration of the workpiece, ensure it is securely supported or clamped to prevent movement during the boring operation.

-

Performing a Bore Job:

-

Select Tools and Setup:

- Choose the appropriate boring bar and cutting tools based on the diameter and depth of the hole to be bored.

- Install the selected tools securely into the boring bar, ensuring they are correctly centered and tightened.

-

Set Cutting Parameters:

- Adjust the cutting speed and feed rate on the machine according to the material being bored (refer to manufacturer’s guidelines).

- Ensure coolant (if applicable) is set up to keep the cutting tools and workpiece cool during operation, reducing friction and tool wear.

-

Start Boring:

- Engage the machine to begin the boring process, following a systematic approach to ensure uniform cutting and accurate dimensions.

- Monitor the cutting progress and adjust feed and speed as necessary to maintain optimal cutting conditions.

-

Measure and Verify:

- Periodically stop to measure the diameter and depth of the bore using precision measuring tools.

- Compare measurements against specifications to ensure the bore meets required tolerances.

-

Finish and Clean Up:

- Once the desired bore diameter and depth are achieved, retract the cutting tools and carefully remove the machine from the workpiece.

- Clean the work area and inspect the bore for smoothness and accuracy.

-

Post-Operation Checks:

- Check for any burrs or irregularities inside the bore and deburr if necessary.

- Inspect the workpiece for overall quality and dimensions to ensure it meets specifications.

-

Maintenance and Storage:

- Clean and maintain the portable line boring machine according to manufacturer’s recommendations.

- Store tools and machine components in a secure and dry location to prevent damage.

-

Safety Considerations:

- Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Follow all safety guidelines provided by the machine manufacturer and applicable regulations.

- Ensure all electrical, hydraulic, or pneumatic connections are secure and in good condition before operation.

By following these steps and safety precautions, you can effectively install a portable line boring machine and perform a bore job with precision and efficiency.

RELATED PRODUCTS

Portable Line Boring Machine ELB40

Original price was: $456.$229Current price is: $229.

Reviews

There are no reviews yet.