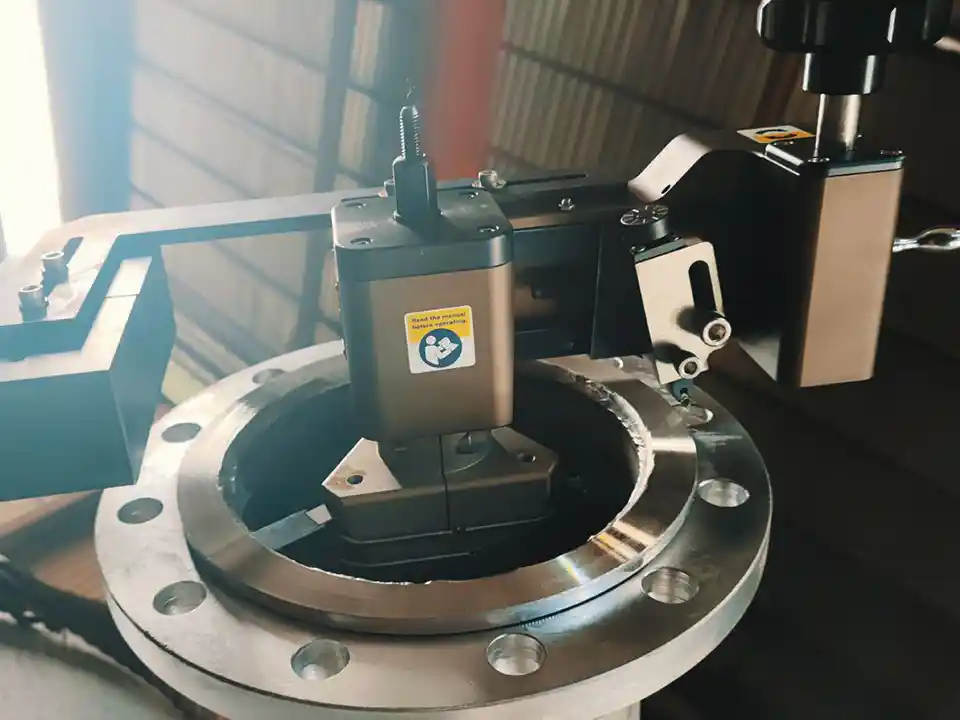

Manual Flange Facer MFF350

Key Features:

- Manually operated, no electric, hydraulic, or air lines necessary.

- Smooth swing operation produces perfectly precise “phonographic” finish.

- Accurately mounts to the flange I.D. in seconds.

- Feeds available for both smooth and stock finish in accordance with ASME B-16.5 standards.

- Made of high strength precision machined materials.

- Sturdy storage / transport case for managing all components.

- Strong hardware that makes setup fast.

- Kit comes up ready to use.

| Weight | 29 kg |

|---|---|

| Dimensions | 68 × 51 × 25 cm |

Original price was: $4,200.$3,500Current price is: $3,500.

Datasheet Download

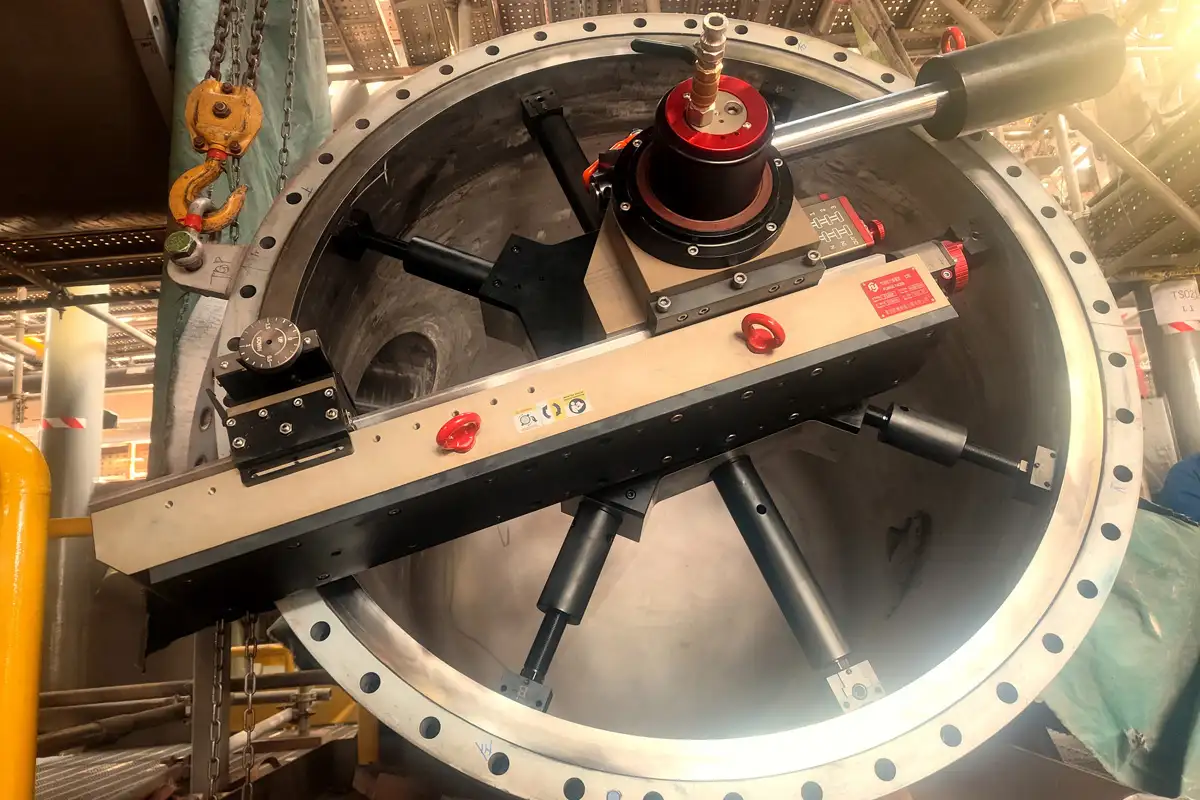

The MFF350 is a hand-operated flange facer designed for precise machining in diverse industrial scenarios. With a clamping range from 1.07″ to 10.63″ (27.2-270 mm), it accommodates a variety of flange sizes, making it adaptable for a range of applications. Its capacity to face diameters between 1.07″ and 14 inches (27.2-355.6 mm) enhances its versatility.

Engineered for durability and compliance with ASME standards, the MFF350 meets the robust demands of industrial environments, proving ideal for tasks such as maintenance, repair, and new installations. Notably user-friendly, the device features an adjustable clamping range and adheres to ASME standards for feed options. This manual flange facer is a reliable tool for professionals seeking precision and high-quality machining results.

| SPECIFICATIONS | INCH | METRIC | |

| Facing Diameter | 1.07 – 14 in. | 27.2-355.6 mm | |

| ID Mounting Diameter | 1.07 – 10.63 in. | 27.2 – 270 mm | |

| Facing Feed Rate | Fine Finsh | 0.005 in./rev | 0.125 mm/rev |

| ASME B16.5 | 0.02 in./rev | 0.5 mm/rev | |

| Tool Post (Vertical) | 1.57 in. | 40 mm | |

| Swing Diameter | 19.5-22.9 in. | 495-582 mm | |

| Power Option | Manual | Hand-power | |

| Working Weight | 9 kgs | ||

| Shipping Weight | 29 kgs |

Customer Reviews

Only logged in customers who have purchased this product may leave a review.

Frequently Asked Questions

What is a flange facer?

A flange facer is a machine used to smooth and prepare the faces of flanges for assembly. Flanges are used to connect pipes and other components in piping systems. They are typically made of steel, stainless steel, or aluminum.

How does a flange facer work?

A flange facer uses a rotating cutting tool to remove material from the face of the flange. The cutting tool is typically a ballnose end mill or a flat end mill. The flange is clamped in place on the machine, and the cutting tool is used to create a smooth, flat surface.

What are the different types of flange facers?

There are two main types of flange facers: internal diameter (ID) flange facers and outer diameter (OD) flange facers. ID flange facers are mounted inside the flange, while OD flange facers are mounted outside the flange.

What are the different applications for a flange facer?

Flange facers are used in a variety of applications, including:

- Installation of new piping systems

- Repair of existing piping systems

- Maintenance of piping systems

- Inspection of piping systems

What are the benefits of using a flange facer?

Using a flange facer provides a number of benefits, including:

- A smooth, flat surface that is essential for proper sealing

- A consistent surface finish that helps to ensure a leak-free joint

- A faster and more efficient way to prepare flanges for assembly

What are the safety precautions to take when using a flange facer?

When using a flange facer, it is important to follow all safety precautions, including:

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection

- Using the correct cutting tool for the application

- Following the manufacturer’s instructions for safe operation

How much does a flange facer cost?

The cost of a flange facer varies depending on the size, type, and features of the machine. In general, flange facers range in price from a few thousand dollars to tens of thousands of dollars.

How do I maintain a flange facer?

It is important to regularly maintain your flange facer to keep it in good working condition. This includes cleaning the machine, lubricating the moving parts, and replacing worn or damaged parts as needed.

sandy –

hello